Fine pitch PCB assembly is a specialized process in electronics manufacturing that deals with components having very small lead spacing. These components, often seen in advanced consumer electronics, telecommunications, and medical devices, require highly precise assembly methods to ensure proper connectivity and functionality. Fine pitch PCB assembly allows manufacturers to achieve higher component density on printed circuit boards, enabling smaller, more efficient, and higher-performing electronic devices.

As electronic devices continue to shrink in size while increasing in complexity, fine pitch technology has become essential. It requires skilled technicians, advanced machinery, and meticulous process control to ensure reliable soldering and alignment of components.

Understanding Fine Pitch Components

Fine pitch components typically have a lead spacing of less than 0.5 mm. This includes devices such as QFPs (Quad Flat Packages), BGAs (Ball Grid Arrays), and CSPs (Chip Scale Packages). Due to the tiny spacing, even minor misalignment during assembly can result in defective boards, making precision and quality control paramount.

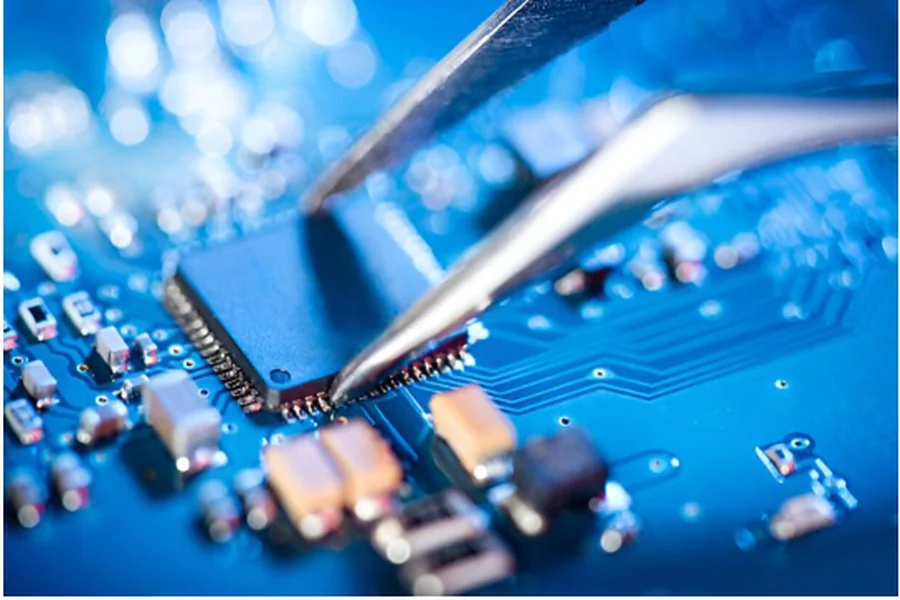

The assembly process involves careful placement, accurate soldering, and thorough inspection. Automated placement machines, reflow soldering ovens, and X-ray inspection systems are standard tools in fine pitch PCB assembly to maintain high accuracy and reduce errors.

The Fine Pitch PCB Assembly Process

Fine pitch PCB assembly requires a combination of advanced techniques and careful process control:

- PCB Preparation: Boards are inspected and prepped for assembly to ensure surfaces are clean and ready for component placement.

- Component Placement: Automated pick-and-place machines accurately position fine pitch components on the PCB.

- Soldering: Reflow soldering is typically used, with precise temperature profiles to avoid defects such as bridging or tombstoning.

- Inspection and Testing: Automated Optical Inspection (AOI), X-ray inspection, and functional testing are conducted to detect misalignments or soldering defects.

- Rework and Quality Assurance: Any defects identified are corrected by skilled technicians, ensuring the final assemblies meet stringent quality standards.

Advantages of Fine Pitch PCB Assembly

Investing in fine pitch PCB assembly provides several benefits for electronics manufacturers:

- High Component Density: Enables more components to fit on a smaller board, leading to compact and lightweight devices.

- Enhanced Performance: Precise assembly ensures reliable connections, reducing the risk of electrical failures.

- Scalability: Suitable for both prototype development and high-volume production without compromising quality.

- Flexibility: Can accommodate a wide range of fine pitch components, supporting diverse applications in advanced electronics.

Applications of Fine Pitch PCB Assembly

Fine pitch PCB assembly is widely used across various industries that demand high precision and reliability:

- Consumer Electronics: Smartphones, tablets, and wearable devices often use fine pitch components for miniaturization and enhanced functionality.

- Telecommunications: Networking equipment and high-speed communication devices require compact boards with densely packed components.

- Medical Devices: Diagnostic and monitoring devices demand precise and reliable assembly to ensure patient safety.

- Automotive Electronics: Advanced driver-assistance systems (ADAS), sensors, and control modules benefit from fine pitch assembly for performance and space optimization.

Choosing a Reliable Partner

Partnering with a professional PCBA China provider ensures that fine pitch PCB assemblies are executed with precision, efficiency, and reliability. Experienced manufacturers offer advanced assembly technologies, rigorous quality control, and scalable production capabilities. This partnership allows businesses to produce high-quality electronic devices while reducing defects, time-to-market, and overall manufacturing costs.

Fine pitch PCB assembly represents a critical capability in modern electronics manufacturing. By leveraging expert services from a trusted provider, companies can ensure that their high-density, high-performance boards meet stringent quality requirements and function flawlessly in demanding applications.